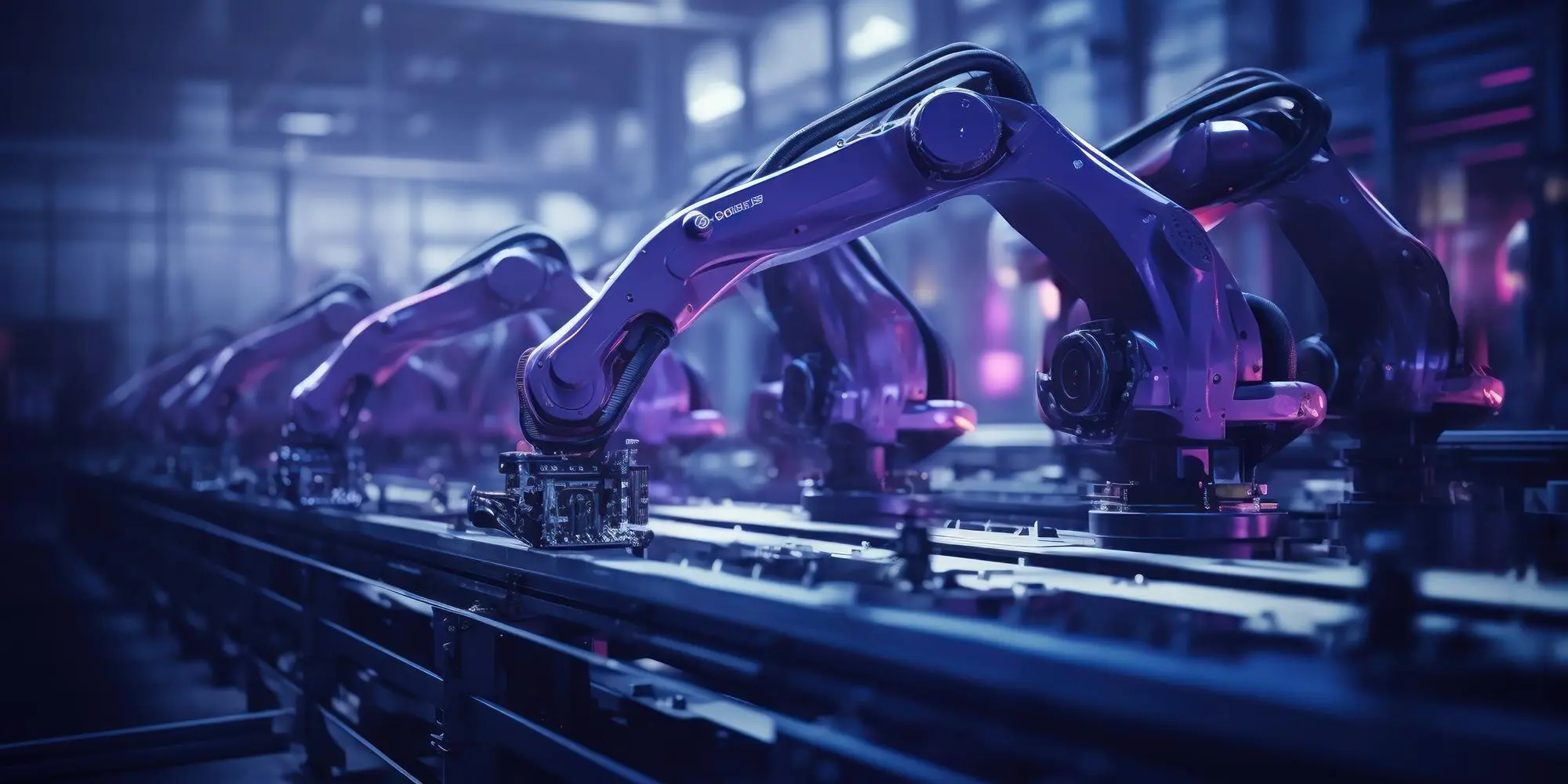

Imagine a factory where machines communicate seamlessly, production lines adapt in real-time, and efficiency reaches new heights. This isn’t science fiction—it’s smart manufacturing, a high-tech reality powered by advanced networking solutions from companies like Cisco. With smart manufacturing, factories combine traditional production techniques with modern digital innovations to create intelligent, automated environments. In this article, we’ll explore how Cisco’s networking technologies are building the factories of the future, making production faster, safer, and more efficient.

What is Smart Manufacturing?

Smart manufacturing uses digital technologies to enhance every step of the production process. In a smart factory, everything—machines, robots, sensors, and computers—is interconnected, sharing information in real-time to optimize operations. It’s like giving the factory a brain that can monitor, adjust, and improve processes automatically.

With IoT devices, automation, and data analytics working together, these factories reduce waste, prevent downtime, increase productivity, and maintain high product quality. Cisco’s networking technologies provide the infrastructure needed to support this complex communication, ensuring all devices can interact smoothly and securely.

Cisco’s Role in Building the Factory of the Future

Cisco, a global leader in networking, offers the tools and technologies required to make smart factories a reality. Here are some of Cisco’s key contributions:

Industrial Ethernet Switches

Cisco’s rugged switches connect everything in the factory—from machines and robots to storage systems and control centers. These switches allow data to flow quickly across the network, ensuring smooth and uninterrupted operations.

Wireless Networking

Mobility is essential in smart factories, where workers use tablets, handheld devices, and automated robots. Cisco’s Wi-Fi 6 technology ensures high-speed, reliable wireless connections across the entire factory floor, supporting seamless communication between mobile devices and machines.

IoT Platforms for Smart Devices

Cisco’s IoT platforms allow manufacturers to connect sensors and smart devices, providing real-time data about equipment status, environmental conditions, and more. This connectivity enables factories to monitor operations closely and make adjustments as needed.

Edge Computing

With Cisco’s edge computing, factories can process data locally, right where it’s generated. This reduces the time it takes to analyze information and allows for faster decision-making—critical when dealing with equipment failures or safety concerns.

Cybersecurity Solutions

As factories become more connected, cybersecurity becomes a top priority. Cisco provides advanced security tools that protect networks from cyberattacks and ensure that only authorized users and devices can access critical systems. Cisco’s Zero Trust security model adds another layer of protection, verifying every device and user on the network.

How Smart Manufacturing Works

Let’s explore how these technologies come together in a Cisco-powered smart factory:

Real-Time Monitoring and Predictive Maintenance

Sensors attached to machines monitor performance in real time, sending data through Cisco’s network infrastructure to a central system. If the data indicates that a machine is likely to break down, the system schedules maintenance before the problem occurs, preventing costly downtime.

Automation and Robotics

Robots in smart factories handle repetitive tasks with precision, guided by real-time data. They can adjust their actions based on changing conditions, ensuring consistent quality. For example, if a product on the assembly line doesn’t meet specifications, the system can automatically remove it or recalibrate the process to correct the issue.

Supply Chain Integration

A smart factory is part of a larger supply chain. Cisco’s networking solutions enable seamless communication between factories and suppliers, ensuring that raw materials arrive just in time and inventory levels remain optimized. This connectivity allows factories to adjust production based on supply and demand without delays.

Energy Management

Cisco’s IoT platforms monitor energy usage across the factory, helping optimize consumption. Systems can turn off equipment when it’s not needed and adjust lighting and HVAC settings based on occupancy. This reduces energy costs and makes the factory more environmentally friendly.

The Benefits of Cisco-Powered Smart Manufacturing

Using Cisco’s networking technologies in smart manufacturing provides several advantages:

- Increased Efficiency: Real-time data and automation reduce human errors, speeding up production.

- Predictive Maintenance: Monitoring equipment health prevents unexpected breakdowns and costly downtime.

- Cost Savings: Optimized energy use and reduced waste lower operational expenses.

- Improved Flexibility: Smart factories can quickly reconfigure production lines to meet changing market demands.

- Enhanced Safety: Automated systems and real-time monitoring reduce the risk of human error and accidents.

A Glimpse into a Cisco-Connected Factory

Imagine a car manufacturing plant where robots assemble vehicles, guided by data from sensors monitoring every step. Workers use tablets to access production data and adjust settings remotely. If a robot encounters a problem, the system alerts the team immediately, allowing for quick fixes without disrupting the production line. Thanks to Cisco’s networking solutions, the factory operates smoothly, efficiently, and securely.

The Future of Manufacturing with Cisco

As technology continues to evolve, smart factories will become even more advanced. New developments in 5G networks, AI-powered analytics, and cloud computing will allow factories to learn from data and optimize processes in real time. Machines will become smarter, making decisions on their own and requiring less human intervention.

Cisco is already working with manufacturers to build these advanced factories, helping companies stay competitive in a rapidly changing market. With Cisco’s networking technology, the factory of the future isn’t just a dream—it’s already here.

Conclusion: Welcome to the Factory of the Future

Smart manufacturing is revolutionizing the way factories operate, making them more efficient, flexible, and secure. Cisco’s networking solutions play a crucial role in this transformation by connecting machines, sensors, and workers through reliable networks. From predictive maintenance to supply chain integration, Cisco technology ensures that smart factories can meet the challenges of the modern economy.

The next time you use a perfectly assembled product, remember that it might have come from a factory powered by Cisco’s technology. The future of manufacturing is here, and with Cisco leading the way, it’s smarter than ever.